High manganese simbiinomira kunze nekuda kwekusaenzana kwayo kupfeka kuramba uye kuoma, zvichiita kuti ive chinhu chakakosha muZvikamu zveCrusher Machine. Nyaya iyi inogona kutsungirira mamiriro ezvinhu akanyanyisa, izvo zvinowedzera kushanda kwekushanda mubasa remigodhi. Zvinoshamisa, makambani anochengetedza zvakanyanya nesimbi yakakwira manganese, kunyanya kana uchishandisaManganese Steel Hammermukushanda kwavo. Semuenzaniso, vanogona kuwana mari yekuchengetedza yegore negore$3.2 mamiriyonikumativi akasiyana-siyana emitengo. Izvi zvinosanganisira madhora 1.95 miriyoni akaponeswa kubva kuderedzwa isina kurongeka nguva, kuvandudza kuwanikwa kwemidziyo kubva ku76.5% kusvika 91.2%. Pamusoro pezvo, mitengo yekukurumidza kugadzirisa inodonha nemadhora mazana matanhatu nemakumi masere ezviuru pagore nekuda kwekutanga kuona dambudziko uye kugadzirisa kwakarongwa, kunyanya kana uchishandira.Manganese Wear Platekuitira kuwedzera kusimba. Uyezve, inoshandaMachining Manganese Steelinobvumira kugadzirwa chaiko kwezvikamu, zvichiwedzera kusimudzira kushanda uye hupenyu hurefu hwemakina munzvimbo dzinodiwa.

Key Takeaways

- High manganese simbiinopa kusaenzana kupfeka kusagadzikana uye kuomarara, zvichiita kuti ive yakakosha kumidziyo yemugodhi.

- Kushandisa yakakwira manganese simbi kunogona kuchengetedza makambani kusvika kumadhora 3.2 miriyoni pagore nekudzikisa nguva yekudzikira uye kugadzirisa mari.

- Basa rekuomesa kugona kwesimbi yakakwira manganese inowedzera kuomarara kwayo pasi pesimba, ichiwedzera kusimba kwayo mumamiriro ezvinhu akaoma.

- Yakakwira manganese simbi zvikamu zvinogona kugara zvakanyanya kwenguva yakareba kupfuura dzimwe nzira, zvichitungamira mukudzikira kuchengetedza uye kutsiva mutengo.

- Kuisa mari musimbi yakakwira manganese kunovandudza kushanda zvakanaka,kuderedza nguvakusvika pa30% uye kuwedzera budiriro.

Yakasiyana Zvivakwa zveYakakwira Manganese Simbi

Maumbirwo uye Chimiro

High manganese simbi, inowanzodanwa seHadfield simbi, ine musanganiswa wakasiyana wezvinhu zvinobatsira kune ayo akasiyana maitiro. Iyo yakajairwa kemikari yemhando yepamusoro manganese simbi inoshandiswa mukupwanya migodhi application inosanganisira:

| Giredhi | C (%) | Mn (%) | P (%) | S (%) | Cr (%) | Ni (%) |

|---|---|---|---|---|---|---|

| GX120Mn13 | 1.05-1.15 | 11-14 | Max. 0.06 | Max. 0.045 | - | - |

| GX120MnCr13-2 | 1.05-1.35 | 11-14 | Max. 0.06 | Max. 0.045 | 1.5-2.5 | - |

| GX120Mn18 | 1.05-1.35 | 16-19 | Max. 0.06 | Max. 0.045 | - | - |

| GX120MnCr18-2 | 1.05-1.35 | 16-19 | Max. 0.06 | Max. 0.045 | 1.5-2.5 | - |

| GX120MnNi13-3 | 1.05-1.35 | 11-14 | Max. 0.06 | Max. 0.045 | - | 3-4 |

| GX120MnMo13-2 | 1.05-1.35 | 11-14 | Max. 0.06 | Max. 0.045 | - | 1.8-2.1 |

Zvikamu zvekutanga zvesimbi yakakwira manganese zvinosanganisira manganese, kabhoni, uye iron.Manganese zvirimo zvinowanzobva pa11% kusvika 14%, nepo kabhoni ichisiyana nemagiredhi. Iyi chaiyo yekuumbwa inoguma mune microstructure iyo inowedzera kupfeka kuramba uye kuoma.

Iyo microstructure yesimbi yakakwira manganese inoita basa rakakosha mukuita kwayo. Iyo inoratidzira heterogeneous chimiro chine yakanaka-grained pearlite uye carbides. Urongwa uhwuinowedzera abrasion kuramba neanenge 16.4%. Izvo zvinyorwa zvinoratidzawo kuomarara kwakanyanya uye ductility, zvichiita kuti ive yakakodzera kune maapplication ayo anoda kuramba kukanganiswa uye abrasive kupfeka.

Basa Kuomesa Hunhu

Imwe yeakamira maficha epamusoro manganese simbi inoshamisakushanda kuomesa kugona. Kana yaiswa pasi pesimba, izvo zvinhu zvinopinda shanduko inowedzera zvakanyanya kuoma kwayo. Ichi chiitiko chinoitika nekuda kwekuumbwa kwe ε-martensite uye mechanical mapatya mukati mesimbi matrix.

Tafura inotevera inoratidza kuomarara kwekuwedzera kunoonekwa mumagiredhi akasiyana esimbi yakakwira manganese pasi pemamiriro ezvinhu:

| Material | Matrix Kuoma (HV) | Worn Sub-surface Kuoma (HV) | Kuwedzera Kuoma (HV) | Nzira yekuomesa |

|---|---|---|---|---|

| Mn13 | 240.2 | 670.1 | 429.9 | Kuumbwa kwe ε-martensite uye mechanical mapatya |

| Mn13-2 | 256.6 | 638.2 | 381.6 | Kuumbwa kwe ε-martensite uye mechanical mapatya |

| Mn18-2 | 266.5 | 713.1 | 446.6 | Kuumbwa kwe ε-martensite uye mechanical mapatya |

Iri basa rinoomesa hunhu rinobvumira yakakwira manganese simbi kutora simba rakakura panguva yekushanda. Nekuda kweizvozvo, inogona kumirisana nepamusoro-inobata mitoro isina fracturing. Iyi pfuma inoita kuti ive yakakosha mumigodhi yekushandisa, uko michina inotarisana nemamiriro akanyanya.

Mukuenzanisa nezvimwe zvinowanzoshandiswa zvicherwa, simbi yakakwira manganese inoratidza kugona kwepamusoro kuomesa basa. Kunyange zvazvo inogona kuratidza simba rakaderera regoho pasi pekuenzanisa kana kuderera-kuderedza kurodha, kushanda kwayo pasi pemamiriro ezvinhu epamusoro haafananidzi. Iyi yakasarudzika musanganiswa wezvivakwa inovimbisa kuti yakakwira manganese simbi inoramba iri sarudzo inosarudzika muindasitiri yemigodhi.

Zvakanakira zveYakakwira Manganese Simbi Pamusoro peZvimwe Zvishandiso

Yakakwira manganese simbi inopa zvakakosha zvakanakira pamusoro pezvimwe zvinhu mumigodhi kupwanya zvikumbiro. Hunhu hwayo hwakasiyana hunobatsirakuwedzera kusimbauye mari-inoshanda, zvichiita kuti ive sarudzo inosarudzwa yemabasa akawanda emigodhi.

Durability uye Hurefu Hweupenyu

Durability chinhu chakakosha mumidziyo yemugodhi. High manganese simbi zvikamu zvinowanzoratidza ahupenyu hwesevhisi hurefukupfuura zvimwe zvinhu, kunyanya pasi pemamiriro ekushanda akajairika. Semuyenzaniso, akakwira manganese simbi mamakisi, akadai seMn22, anoratidza kupfeka kwakasiyana-siyana uye kuramba. Aya liners anogona kugara pakati250 kusvika 500 maawamune abrasive mamiriro, zvakanyanya outlasting standard manganese simbi.

Mukuenzanisa, alloy simbi zvikamu zvinogona kugara kupfuurazvakapetwa katatukupfuura high manganese simbi pasi pemamiriro akafanana ekushanda. Ongororo dzemuLabhoritari dzinosimbisa kuti alloy simbi shaya mahwendefa anopokana kupfeka zviri nani, kunyanya munzvimbo dzine abrasive. Tafura inotevera inopfupikisa kusimba kwemaitiro epamusoro manganese simbi maringe nesimbi yealloy:

| Property | High Manganese Steel | Alloy Steel |

|---|---|---|

| Pfeka Resistance | Inowanzopfeka nekukurumidza mune mamwe mamiriro | Inoramba kupfeka zviri nani, inogara kwenguva refu |

| Impact Resistance | Good impact resistance | Kuramba kuri pakati nepakati |

| Kuoma | Inogona kushanda-yakaoma asi kuderedza kuoma kwese | Kuoma kwepamusoro (HRC 48-51) |

| Kugara kwenguva refu | Kazhinji isingagare yakasimba kupfuura alloy simbi | Inogona kugara katatu kwenguva refu |

| Kuchinja Kunogoneka | Inogona kugadziriswa ne chromium/molybdenum | Hazviwanzo gadziridzwa |

Iko kushanda-kuomesa kugona kwesimbi yakakwira manganese inobvumira kuti itore simba rakakosha panguva yekushanda. Ichi chivakwa chinowedzera kusimba kwayo, ichiita kuti ive yakakodzera kune yakakwira-impact application mumigodhi.

Mutengo-Kubudirira

Mutengo-kushanda ndeimwe yakakosha mukana weyakakwira manganese simbi. Kunyange zvazvo mari yekutanga ingave yakakwirira kudarika dzimwe nzira, mari yekugara kwenguva refu inowanzopfuura mari iyi. Yakakwira manganese simbi zvikamu zvinowanzopa hupenyu hwesevhisi hwakawedzerwa zvakanyanya zvichienzaniswa nezvimwe zvinhu. Uhu hurefu hwehupenyu hunoturikira mukuderedzwa kudzoreredzwa frequency uye kuderera kwekugadzirisa mutengo.

Uyezve, kushandiswa kwesimbi yakakwira manganese kunogona kutungamira kukuchengetedza kwakanyanya mumitengo yekushanda. Makambani anogona kuderedza nguva yekudzika uye kugadzirisa mari, izvo zvinobatsira mukubudirira kwese. Semuenzaniso, yakakwira chrome alloy simbi zvikamu zvinogona kugara katatu kana mana kureba kupfuura yakajairwa manganese simbi mahwendefa. Uhu hurefu hwehupenyu hunoderedza kudiwa kwekugara uchitsiviwa, zvichizopedzisira zvaita kuti mitengo yakaderera.

Zvishandiso zveYakakwira Manganese Simbi muMigodhi Kupwanya

Crusher Liners

High manganese simbiinoita basa rakakosha mukugadzirwa kwemacrusher liners. Aya liner zvinhu zvakakosha mumhando dzakasiyanamaindasitiri anopfeka zvakanyanya, anosanganisira kuchera, kuchera migodhi, kuchera, uye chikamu chemarasha. Ivo vanomira zvakanyanya kukweshana kwezvinhu uye kupwanya zvinokonzeresa, kuve nechokwadi chekushanda kwakagadzikana kwemacrusher. Iyo yepamusoro yekupfeka kuramba uye yakawedzera hupenyu hwesevhisi yeakakwira manganese simbi inoita kuti ive yakakodzera kune rinorema-basa rekushandisa.

Tafura inotevera inotaridza kuvandudzwa kwekuita kunocherechedzwa kana uchishandisa yakakwira manganese simbi mune crusher liner:

| Kuvandudza Kuita | Tsanangudzo |

|---|---|

| Yakanakisa Wear Resistance | High-manganese simbi liners inoratidzakusarudzika kupfeka kuramba, kuwedzera hupenyu hwemidziyo. |

| Kuzviomesera Zvinhu | Iwo liner anowedzera mukuoma kwepamusoro nekufamba kwenguva, achiwedzera kupfeka kusagadzikana uye kushanda zvakanaka. |

| Kuvandudza Crusher Kubudirira | Kuomarara kwepamusoro kunotungamira kune kudzvanya kunoshanda, kuderedza kurasikirwa kwesimba nekuvandudza kugona kwekugadzira. |

| Yakaderedzwa Equipment Maintenance Frequency | Kuwedzera kuoma kwepamusoro kunoguma nekupfeka zvishoma nezvishoma, kuderedza kudiwa kwekugara uchitsiva. |

| Yakavandudzwa Yese Kubudirira Kwekugadzira | Hupenyu hwesevhisi hurefu uye nguva yakaderedzwa inosimudzira kuenderera kwemutsara wekugadzira uye kubereka kwakazara. |

| Yakasimba Impact Resistance | Iwo ma-liners anomira zvakanyanya kukanganisa, kuchengetedza kushanda kwakagadzikana uye kuderedza mari yekugadzirisa. |

| Kuderedzwa Kwemari Yekushanda | Kusawanzogadzirisa uye kutsiva kunoderedza mari yekushandisa uye kunatsiridza mabhenefiti ehupfumi. |

Jaw uye Cone Crushers

High manganese simbi zvakanyanyainowedzera kushanda kweshaya uye cone crushers. Inenge 70% yeshaya uye cone crushersmuindasitiri yemigodhi shandisa yakakwira manganese simbi zvikamu. Nyaya iyi inopakusimba kunoshamisa uye kusimba, yakakosha pakubata kuvhunduka munzvimbo dzakanyanya-kudzvanywa.

Iyo yakasarudzika zvimiro zveyakakwirira manganese simbi inobvumira kuti itore uye iparadze kuvhunduka simba zvinobudirira. Izvi zvinodzivirira kutsemuka kana kutsemuka, izvo zvakakosha pakugadzirisa zvinhu zvakaoma. Aya mapoinzi anotevera anopfupikisa mabhenefiti epamusoro manganese simbi mushaya uye cone crushers:

- Manganese simbi inoshanda-inoomesa nemhedzisiro yega yega, ichiwedzera kuramba kwayo kune abrasion.

- Inochengetedza kuoma kwepamusoro, inotora simba rekuita simba pasina kutsemuka.

- Uku kusanganiswa kunobvumira kuti iite zvakanaka mumamiriro ebrasive uye yakakwirira-impact.

Nekudzikisira kudiwa kwekudzokororwa kwechikamu, yakakwira manganese simbi inoderedza nguva yekudzikira uye inowedzera kugadzirwa kwese. Kubhadhara kwaro kunobva pakuwedzera kwehupenyu hwezvikamu, izvo zvinotungamirira kuderera kwekugadzirisa zvinodiwa.

Mhedzisiro yeYakakwira Manganese Simbi paKubudirira uye Kubudirira

Yakaderedzwa Downtime

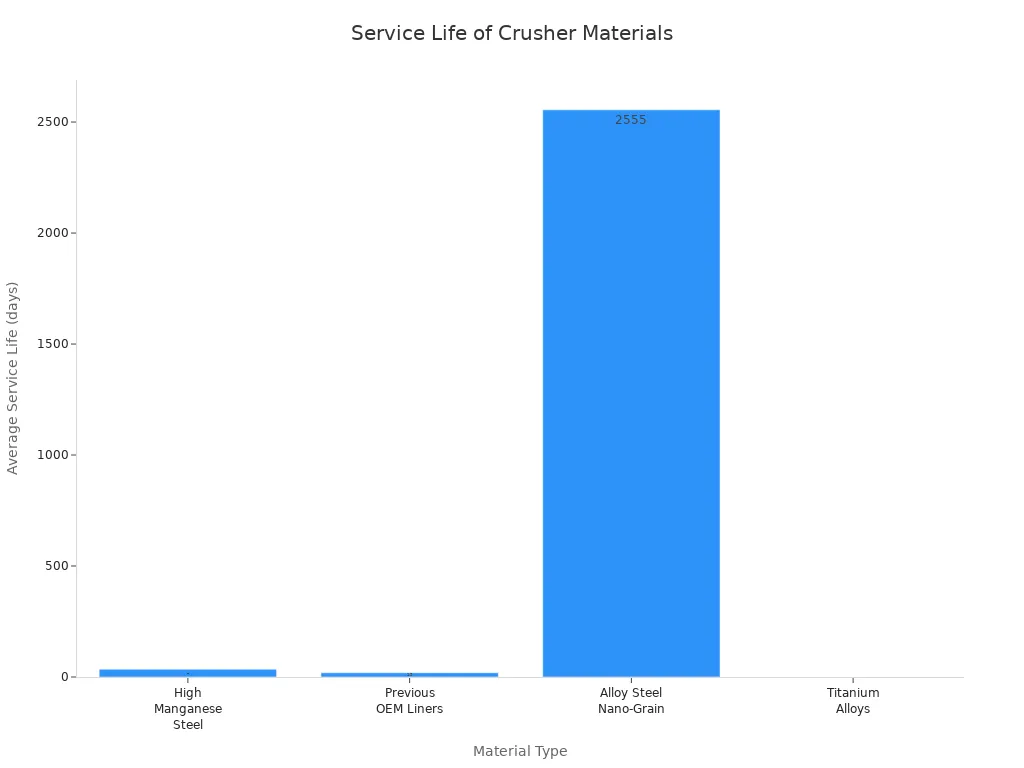

Yakakwira manganese simbi inoderedza zvakanyanya kuderera mumabasa emigodhi. Kugara kwayo uyekupfeka kurambakutungamirira kuhupenyu hurefu hwebasa rezvikamu. Semuenzaniso, yakakwirira manganese simbi liners inogona kugara avhareji ye35 mazuva, zvichienzaniswa nemazuva gumi nemapfumbamwe chete ekare eOEM liners. Kuvandudzwa uku kunobvumira makambani emigodhi kuchengetedza mashandiro anoramba achiita pasina kuvhiringwa nguva nenguva kune dzimwe nzvimbo.

| Material Type | Avhareji Youpenyu Hwebasa | Notes |

|---|---|---|

| Yakakwira Manganese Simbi (Xtralloy) | 35 mazuva | Kuvandudza kwakakosha pane yapfuura OEM liner. |

| Yakapfuura OEM Liners | 19 mazuva | Hupenyu hwesevhisi hwakaderera uchienzaniswa neXtralloy. |

| Alloy Steel ine Nano-Grain Forging | 5-7 makore | Hupenyu hurefu kupfuura yakakwirira manganese simbi. |

| Titanium Alloys | 7-9 makore | Hupenyu hwepamusoro huchienzaniswa nesimbi yakakwira manganese. |

Hurefu hwehupenyu hwepamusoro manganese simbi zvikamu zvinotungamira kune kushomeka kwekugadzirisa kuvharika. Vatengi vakashuma kuderedzwa kwekuchengetedza kuderera kusvika30%mushure mekuchinja kune yakakwirira manganese simbi zvikamu. Kudzikiswa uku hakungokwidziri zvibereko chete asi kunopawo mari yakawanda yekuchengetedza.

Enhanced Performance Metrics

Yakakwira manganese simbi inosimudzira akati wandei ekuita metrics mumigodhi kupwanya michina. Iyo yakasarudzika zvimiro inovandudza kupfeka kuramba, kusimba, uye kusimba kwese. Nekuda kweizvozvo, migodhi inoitika:

- Pfeka Resistance: Yakakwira manganese simbi inova yakaoma nekufamba kwenguva kana yaiswa mukukwesha, zvichiita kuti ive yakanakira maapplication uko kupfeka kuri kunetseka.

- Kuoma: Kuomarara kwechinyorwa kunowedzera kugona kwayo kushingirira kukanganiswa uye masimba anokuvadza, akakosha munzvimbo dzemigodhi.

- Kugara kwenguva refu: Kugara kwakazara kunovandudzwa, zvichiita kuti kuderedzwa kuderedzwa uye kuderera kwemitengo yekugadzirisa.

Iyo yekufembera modhi yehupenyu hwese hwekupwanya mahwendefa inoratidza yakaderera mudzi inoreva square mhosho (RMSE) ye0.0614 maawa. Uku kurongeka kunoratidza kuti simbi yakakwira manganese inowedzera zvakanyanya kubereka, nehupenyu hunobva pa746 kusvika 6902 maawa. Makambani anotarisa pamhando dzemhando anoona kuvandudzwa kwechigadzirwa kusvika ku20%.

Nekudyara mune yakakwira manganese simbi zvikamu, mashandiro emigodhi anogona kuita zvirinani kuita metrics uye kushanda zvakanaka.

High manganese simbi's properties inoita kuti ive yakakosha mumigodhi yekupwanya zvikumbiro. Kuumbwa kwayo kwakasiyana kunowedzera kusimba, kusakara, uye kusimba. Ichi chinyorwa chinovandudza zvakanyanya kubereka uye kuchengetedza mari yemabasa emigodhi. Mabhenefiti akakosha anosanganisira:

- Yakawedzerwa nguva yekugadzirisa ne30–40%

- Yakaderedzwa frequency yechikamu chinotsiviwa

- Mari yekushandisa yakaderera

Kudiwa kwesimbi yakakwira manganese ndikoinotarisirwa kusimukanekuda kwekuita kwayo kusingaenzaniswi mumamiriro ezvinhu akaomarara. Sezvo tekinoroji dzemigodhi dzichishanduka, kuenderera mberi kwekushandiswa kwesimbi yakakwira manganese kunoramba kwakakosha pakushanda kwakanaka.

| Property/Basa | Tsanangudzo |

|---|---|

| Deoxidising Agent | Inobvisa tsvina yeokisijeni nesarufa kubva musimbi yakanyungudutswa, inovandudza simba nekusimba. |

| Alloy Strengthener | Inokwidziridza kuoma, kuomarara, uye kupfeka kuramba nekugadzira akagadzikana makomisheni nekabhoni. |

| Hardenability Booster | Inowedzera kuoma, kuita simbi yakakodzera yezvimiro zvekushandisa pasi pekunetseka. |

| High-Manganese Simbi | Iine 12–14% manganese, inozivikanwa neakasarudzika basa-kuomesa zvivakwa, yakanakira kumigodhi. |

FAQ

Chii chinonzi high manganese simbi?

High manganese simbi ndeye alloy ine 11-14% manganese. Iyo inozivikanwa nekusimba kwayo kwakasarudzika uye kupfeka kuramba, ichiita kuti ive yakakodzera kumigodhi application.

Yakakwira manganese simbi inoshanda sei yakaoma?

Yakakwira manganese simbi inoshanda inoomesa kana ichiiswa musimba. Iyi nzira inowedzera kuoma kwayo, ichiibvumira kutora simba rakawanda uye kuramba kupfeka.

Ndeapi mashandisirwo makuru esimbi yakakwira manganese mumigodhi?

Yakakwira manganese simbi inonyanya kushandiswa mucrusher liners,shaya dzinopwanya, uye zvinopwanya makoni. Kugara kwayo kunoita kuti ive yakakodzera kune yakakwirira-impact uye abrasive nharaunda.

Nei yakakwirira manganese simbi inodhura-inoshanda?

Kunyange zvazvo yakakwirira manganese simbi inogona kuva yepamusoro mari yokutanga, ayo refu basa upenyu uyekuderedzwa kwezvinodiwa zvekuchengetedzazvinotungamirira kukuchengetedza kwakakosha nekufamba kwenguva.

Yakakwira manganese simbi inofananidzwa sei nezvimwe zvinhu?

Yakakwira manganese simbi inopa yepamusoro kupfeka kuramba uye kuomarara kana zvichienzaniswa nezvimwe zvinhu zvakaita sesimbi alloy. Izvi zvinoita kuti ive sarudzo inosarudzika yekuda maapplication emigodhi.

Nguva yekutumira: Oct-24-2025