Tsanangudzo

Kuti ugadzire zvigadzirwa zvemhando yepamusoro pamutengo wakaderera nehunyanzvi hwepamusoro uye kuvimbika, unofanirwa kusarudza zvipfeko zvakagadziridzwa kune yako yekupwanya application. Zvinhu zvikuru zvekufunga nezvazvo sezvinotevera:

1. Mhando yematombo kana zvicherwa zvekupwanywa.

2. Material particle size, hunyoro hwemukati uye Mohs kuoma giredhi.

3. Zvinhu uye hupenyu hwemabheti ekurova akamboshandiswa.

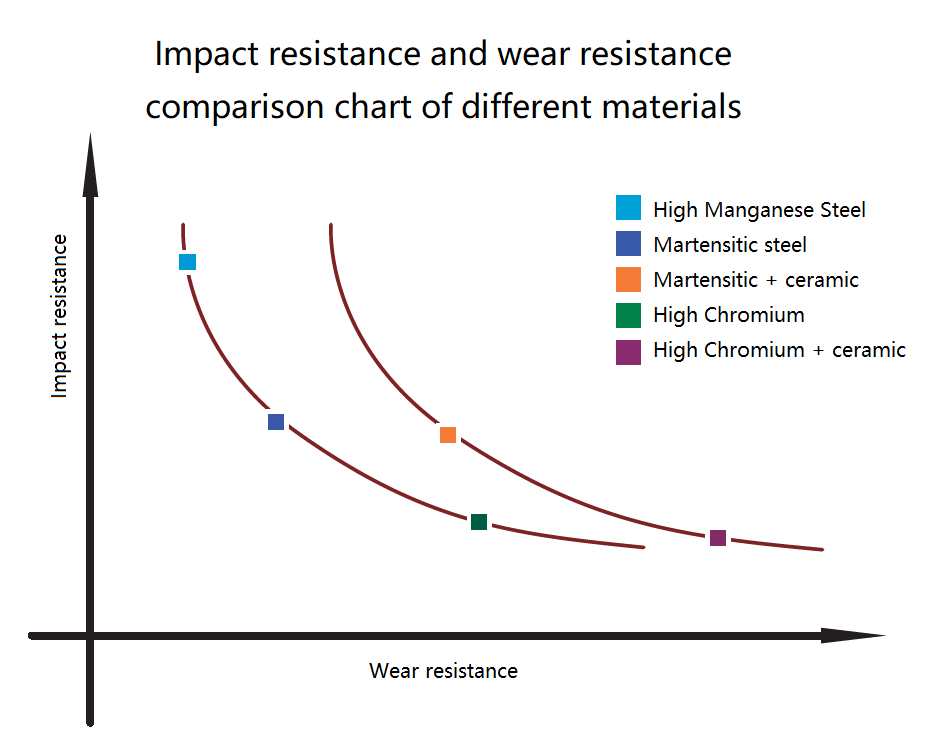

Kazhinji, kupfeka kuramba (kana kuomarara) kwesimbi-yakaiswa simbi inodzivirira zvinhu zvinozodzikisira kupikisa kwayo (kana kuoma). Iyo nzira yekumisikidza ivhu musimbi matrix zvinhu inogona kuwedzera zvakanyanya kupfeka kwayo kuramba pasina kukanganisa kukanganisa kwayo.

High Manganese Steel

Yakakwira manganese simbi ndeye isingapfeki zvinhu zvine nhoroondo refu uye yakashandiswa zvakanyanya mukukanganisa macrusher. Yakakwirira manganese simbi ine yakatanhamara kukanganisa kupikisa. Iko kupfeka kupikisa kunowanzoenderana nekumanikidzwa uye kukanganisa pamusoro payo. Kana kukanganiswa kukuru kwakaiswa, iyo austenite chimiro chiri pamusoro chinogona kuomeswa kusvika HRC50 kana kupfuura.

Yakakwira manganese simbi simbi sando dzinowanzo kurudzirwa kupwanya kwekutanga nezvinhu zvehukuru hwekudya particle size uye kuomarara kwakaderera.

Kemikari yakagadzirwa nesimbi yakakwira manganese

| Material | Kuumbwa Kwemakemikari | Machanical Property | ||||

| Mn% | Cr% | C% | Si% | Ak/cm | HB | |

| Mn14 | 12-14 | 1.7-2.2 | 1.15-1.25 | 0.3-0.6 | > 140 | 180-220 |

| Mn15 | 14-16 | 1.7-2.2 | 1.15-1.30 | 0.3-0.6 | > 140 | 180-220 |

| Mn18 | 16-19 | 1.8-2.5 | 1.15-1.30 | 0.3-0.8 | > 140 | 190-240 |

| Mn22 | 20-22 | 1.8-2.5 | 1.10-1.40 | 0.3-0.8 | > 140 | 190-240 |

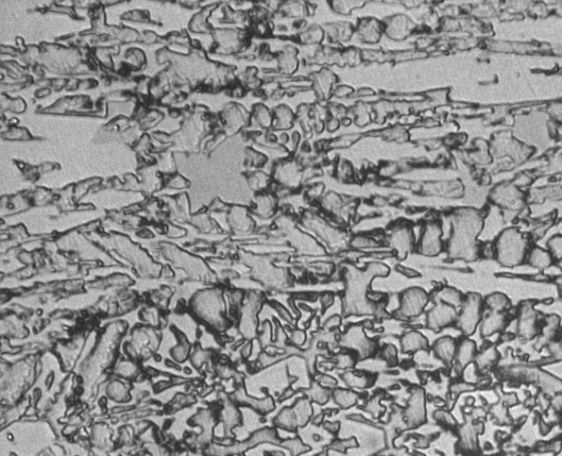

Microstructure yepamusoro manganese simbi

Martensitic Steel

Martensite chimiro chinoumbwa nekukurumidza kutonhora kweyakazara yakazara kabhoni simbi. Maatomu ecarbon anogona kupararira kunze kwemartensite chete mukukurumidza kutonhora mushure mekupisa. Martensitic simbi ine kuomarara kwepamusoro pane yakakwirira-manganese simbi, asi kupikisa kwayo kunodzikiswa. Kuoma kwesimbi yemartensitic iri pakati peHRC46-56. Zvichienderana neaya zvivakwa, martensitic simbi blow bar inowanzo kukurudzirwa kupwanya maapplication uko kune yakaderera maitiro asi yakakwirira kupfeka kuramba kunodiwa.

Microstructure yemartensitic simbi

High Chromium White Iron

Mune yakakwira chromium chena iron, kabhoni inosanganiswa nechromium muchimiro chechromium carbide. Yakakwira chromium chena iron ine yakatanhamara kupfeka kuramba. Mushure mekurapwa kwekupisa, kuomarara kwayo kunogona kusvika 60-64HRC, asi kupikisa kwayo kunodzikiswa. Kuenzaniswa nesimbi yakakwira manganese uye martensitic simbi, yakakwira chromium cast iron ine yakanyanya kupfeka kuramba, asi kupikisa kwayo ndiko kwakadzikira.

Mune yakakwira chromium chena iron, kabhoni inosanganiswa nechromium muchimiro chechromium carbide. Yakakwira chromium chena iron ine yakatanhamara kupfeka kuramba. Mushure mekurapwa kwekupisa, kuomarara kwayo kunogona kusvika 60-64HRC, asi kupikisa kwayo kunodzikiswa. Kuenzaniswa nesimbi yakakwira manganese uye martensitic simbi, yakakwira chromium cast iron ine yakanyanya kupfeka kuramba, asi kupikisa kwayo ndiko kwakadzikira.

Kemikari yemhando yepamusoro chromium chena iron

| ASTM A532 | Tsanangudzo | C | Mn | Si | Ni | Cr | Mo | |

| I | A | Ni-Cr-Hc | 2.8-3.6 | 2.0 Max | 0.8 Max | 3.3-5.0 | 1.4-4.0 | 1.0 Max |

| I | B | Ni-Cr-Lc | 2.4-3.0 | 2.0 Max | 0.8 Max | 3.3-5.0 | 1.4-4.0 | 1.0 Max |

| I | C | Ni-Cr-GB | 2.5-3.7 | 2.0 Max | 0.8 Max | 4.0 Max | 1.0-2.5 | 1.0 Max |

| I | D | Ni-HiCr | 2.5-3.6 | 2.0 Max | 2.0 Max | 4.5-7.0 | 7.0-11.0 | 1.5 Max |

| II | A | 12Kr | 2.0-3.3 | 2.0 Max | 1.5 Max | 0.40-0.60 | 11.0-14.0 | 3.0 Max |

| II | B | 15CrMo | 2.0-3.3 | 2.0 Max | 1.5 Max | 0.80-1.20 | 14.0-18.0 | 3.0 Max |

| II | D | 20CrMo | 2.8-3.3 | 2.0 Max | 1.0-2.2 | 0.80-1.20 | 18.0-23.0 | 3.0 Max |

| III | A | 25Kr | 2.8-3.3 | 2.0 Max | 1.5 Max | 0.40-0.60 | 23.0-30.0 | 3.0 Max |

Microstructure yeHigh Chromium White Iron

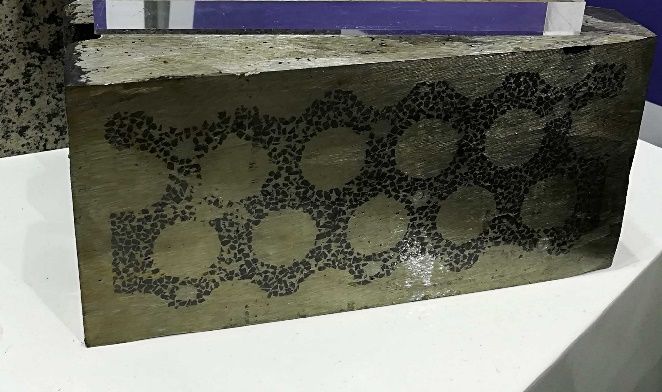

Ceramic-Metal Composite Material (CMC)

CMC chinhu chinopfekwa chinosanganisa kusimba kwakanaka kwezvinhu zvesimbi (martensitic simbi kana yakakwira-chromium cast iron) nekuomarara kwakanyanya kweindasitiri ceramics. Ceramic particles yehukuru chaihwo inobatwa zvakanyanya kuti iite porous body of ceramic particles. Simbi yakanyungudutswa inopinda zvizere mukati memukati meiyo ceramic chimiro panguva yekukanda uye inosanganisa zvakanaka nehari.

Iyi dhizaini inogona kunyatso kuvandudza maitiro ekurwisa-kupfeka kwechiso chekushanda; panguva imwecheteyo, iyo huru yebhari yekurova kana nyundo ichiri kugadzirwa nesimbi kuti ive nechokwadi chekushanda kwayo kwakachengeteka, kunyatsogadzirisa kupokana pakati pekupfeka kuramba uye kukanganisa kupikisa, uye inogona kuchinjirwa kune akasiyana ekushanda mamiriro. Inovhura munda mutsva wekusarudzwa kwezvipfeko zvepamusoro-soro kune vazhinji vevashandisi, uye kugadzira hupfumi huri nani.

a.Martensitic Steel + Ceramic

Kuenzaniswa neyakajairwa martensitic blow bar, iyo martensitic ceramic blow sando ine kuomarara kwepamusoro pane yakapfekwa pamusoro, asi kupikisa kwesando yekurova hakuzodzike. Mumamiriro ekushanda, iyo martensitic ceramic blow bar inogona kuva yakanaka kutsiva application uye kazhinji inogona kuwana kanokwana ka2 kana kureba hupenyu hwesevhisi.

b.High Chromium White Iron +Ceramic

Kunyangwe yakajairwa yakakwira-chromium iron blow bar yatove neyakanyanya kupfeka kuramba, kana kupwanya zvinhu zvine kuomarara kwakanyanya, senge granite, mamwe mabhawa asingapfekeri anowanzo shandiswa kurebesa hupenyu hwavo hwekushanda. Muchiitiko ichi, high-chromium cast iron ine yakaiswa ceramic blow bar ndiyo mhinduro iri nani. Nekuda kwekumisikidzwa kweceramics, kuomarara kwekupfeka kwesando yekurova kunowedzera kuwedzera, uye kusagadzika kwayo kunovandudzwa zvakanyanya, kazhinji kaviri kana hupenyu hurefu hwesevhisi pane yakajairika high chromium chena iron.

Zvakanakira zveCeramic-Metal Composite Material (CMC)

(1) Yakaoma asi isina brittle, yakasimba uye isingapfeki, kuwana chiyero cheviri chekusapfeka uye kusimba kwepamusoro;

(2) Kuomarara kweceramic ndeye 2100HV, uye kusamira kwekupfeka kunogona kusvika 3 kusvika ku4 nguva yeakajairika alloy zvinhu;

(3) Yakasarudzika chirongwa dhizaini, inonzwisisika kupfeka mutsara;

(4) Hupenyu hurefu hwebasa uye hupfumi hwepamusoro.

Product Parameter

| Machine Brand | Machine model |

| Metso | LT-NP 1007 |

| LT-NP 1110 | |

| LT-NP 1213 | |

| LT-NP 1315/1415 | |

| LT-NP 1520/1620 | |

| Hazemag | 1022 HAZ791-2 HAZ879 HAZ790 HAZ893 HAZ975 HAZ817 |

| 1313 HAZ796 HAZ857 HAZ832 HAZ879 HAZ764 HAZ1073 | |

| 1320 HAZ1025 HAZ804 HAZ789 HAZ878 HAZ800A HAZ1077 | |

| 1515 HAZ814 HAZ868 HAZ1085 HAZ866 HAZ850 HAZ804 | |

| 791 HAZ565 HAZ667 HAZ1023 HAZ811 HAZ793 HAZ1096 | |

| 789 HAZ815 HAZ814 HAZ764 HAZ810 HAZ797 HAZ1022 | |

| Sandvik | QI341 (QI240) |

| QI441(QI440) | |

| QI340 (I-C13) | |

| CI124 | |

| CI224 | |

| Kleemann | MR110 EVO |

| MR130 EVO | |

| MR100Z | |

| MR122Z | |

| Terex Pegson | XH250 (CR004-012-001) |

| XH320-nyowani | |

| XH320-yekare | |

| 1412 (XH500) | |

| 428 Tracpactor 4242 (300 yakakwirira) | |

| Powerscreen | Trackpactor 320 |

| Terex Finlay | I-100 |

| I-110 | |

| I-120 | |

| I-130 | |

| I-140 | |

| Rubblemaster | RM60 |

| RM70 | |

| RM80 | |

| RM100 | |

| RM120 | |

| Tesab | RK-623 |

| RK-1012 | |

| Extec | C13 |

| Telsmith | 6060 |

| Keestrack | R3 |

| R5 | |

| McCloskey | I44 |

| I54 | |

| Lippmann | 4248 |

| Gondo | 1400 |

| 1200 | |

| Striker | 907 |

| 1112/1312 -100mm | |

| 1112/1312 -120mm | |

| 1315 | |

| Kumbee | No1 |

| No2 | |

| Shanghai Shanbao | PF-1010 |

| PF-1210 | |

| PF-1214 | |

| PF-1315 | |

| SBM/Henan Liming/Shanghai Zenith | PF-1010 |

| PF-1210 | |

| PF-1214 | |

| PF-1315 | |

| PFW-1214 | |

| PFW-1315 |