Kukandira zvinhuinogadzira zvigadzirwa seaJaw Crusher Machine or Gyratory Crusher. Vanobatsira kugadzira zvese kubvaZvikamu zveCone Crusherku aManganese Steel Hammer. Chisarudzo chakanaka chine basa. Tarisa tafura iyi kubva kumusoro kweEuropean foundry:

| Year Cast Iron Output | 23,000 matani |

| Defect Rate | 5–7% |

Materials sainzi inovhara simbi, ceramics, polymers, uye macomposites. Kuziva iyo chaiyo yekukanda zvinhu kunobatsira mainjiniya kusimudzira mhando uye kucheka tsvina.

Key Takeaways

- Kusarudza iyo chaiyo yekukanda zvinhu, sesimbi, simbi,aluminium, kana mapurasitiki, anokanganisa zvakananga kunaka kwechigadzirwa, mutengo, uye kuita.

- Ferrous materials ine iron uye yakasimba asi inogona kuita ngura, ukuwo zvinhu zvisina ferrous zvakaita sealuminium nemhangura zvinodzivirira ngura uye zvakareruka.

- Plastics uye ceramics zvinopa zvakasarudzika mabhenefiti senge corrosion resistance uye kupisa kushivirira, zvichiita kuti ive yakakodzera kune yakakosha maapplication.

Mhando Huru dzeKukanda Material

Ferrous Casting Material: Simbi uye Simbi

Ferrous casting materials zvinosanganisira iron nesimbi. Masimbi aya ane iron sechinhu chawo chikuru. Vanoita basa guru mumichina inorema uye kuvaka. Simbi nesimbi zvine zvinhu zvakasiyana. Tafura iri pazasi inoratidza kuti vanoenzanisa sei:

| Property / Feature | Cast Iron | Simbi (kusanganisira zvinyoro uye carbon steels) |

|---|---|---|

| Carbon Content | 2–4.5% | 0.16–2.1% |

| Mechanical Properties | High compressive simba; brittle | Ductile; kusimba kwesimba kunosiyana |

| Corrosion Resistance | Zvirinani mumhepo yakasviba | Inoora nekukurumidza |

| Machinability | Nyore (grey iron); yakaoma (white iron) | Zvakanaka, zvinosiyana nemhando |

| Applications | Engine blocks, brake rotors | Magiya, zvitubu, zvikamu zvemotokari |

Simbi yekukanda zvinhu inoshanda nemazvo kumabhuroko einjini uye dzimba dzepombi.Simbi yekukanda zvinhuinokodzera magiya, zvitubu, uye zvikamu zvemotokari zvakawanda. Mhando imwe neimwe inounza simba rayo patafura.

Non-Ferrous Casting Material: Aluminium, Copper, Magnesium, Zinc

Zvisiri-ferrous casting materials hazvina simbi sechinhu chikuru. Aluminium, mhangura, magnesium, uye zingi ndezveboka iri. Masimbi aya akareruka kupfuura simbi nesimbi. Aluminium yekukanda zvinhu yakakurumbira kune zvikamu zvemotokari uye mafuremu endege. Copper casting material inoshanda muzvikamu zvemagetsi nekuti inofambisa magetsi zvakanaka. Magnesium uye zinc yekukanda zvinhu zvinobatsira kugadzira zvikamu zvisingaremi zvemagetsi nematurusi. Masimbi asina-ferrous anodzivisa ngura uye anopa simba rakanaka kune uremu hwavo.

Zvimwe Zvishandiso zvekukanda: Plastiki uye Ceramics

Zvimwe zvekukandira hazvisi simbi zvachose. Plastiki uye ceramics inopa mabhenefiti akasiyana. Plastics inogona kuumba zvimiro zvakaoma uye kuramba corrosion. Ceramics inomira kusvika pakupisa kukuru. Vanhu vekare vaishandisa ceramic casting material pakunyungudisa mhangura. Makeramiki emazuva ano, se nano-zirconia, anoratidza kunyange kuita zviri nani. Vane simba rekukotama rakakwirira, kusimba, uye kuramba kukwenya. Aya maceramics anobatsira kugadzira zvikamu zvitete, zvakasimba zvemafoni nemawachi.

Plastics uye ceramics anovhura mikova mitsva yekukanda zvinhu, kunyanya uko kupikisa kupisa kana maumbirwo akakosha.

Zvivakwa uye Kushandiswa kweKukanda Material Type

Iron Casting Material

Simbi yekukanda zvinhu inomira pachena nekuda kwesimba rayo mukumanikidza. Vanhu vanowanzoishandisa kuita makolamu, mabhuroko einjini, uye michina inorema. Grey cast iron ine kabhoni flakes, iyo inoita kuti zvive nyore kugadzira asi zvakare brittle. White cast iron, ine kabhoni sesimbi carbide, inopa zvirinani kusimba uye kusimba.

- Strengths:

- Inobata mitoro inorema zvakanaka.

- Yakanaka kune zvikamu zvisingapendi zvakanyanya.

- Utera:

- Brittle uye inogona kuputsa pasi pekunetseka.

- Inowanzoita ngura, kunyanya munzvimbo dzine hunyoro.

Kuwedzera zvinhu zvakaita sesilicon, nickel, kana chromium zvinogona kukwidziridza corrosion kuramba uye kusimba. Kugara uchipenda uye kuongorora kunobatsira kudzivirira ngura uye kuchengetedza masimbi ari muchimiro chakanaka.

Miedzo inoratidza kuti jecha rinoshandiswa mukukanda simbi rinogona kubata kupisa kwakanyanya, asi kupera kwepamusoro kunoenderana nekukura kwejecha rezviyo uye chimiro. Izvi zvinokanganisa kutsetseka kana kushata kwechigadzirwa chekupedzisira.

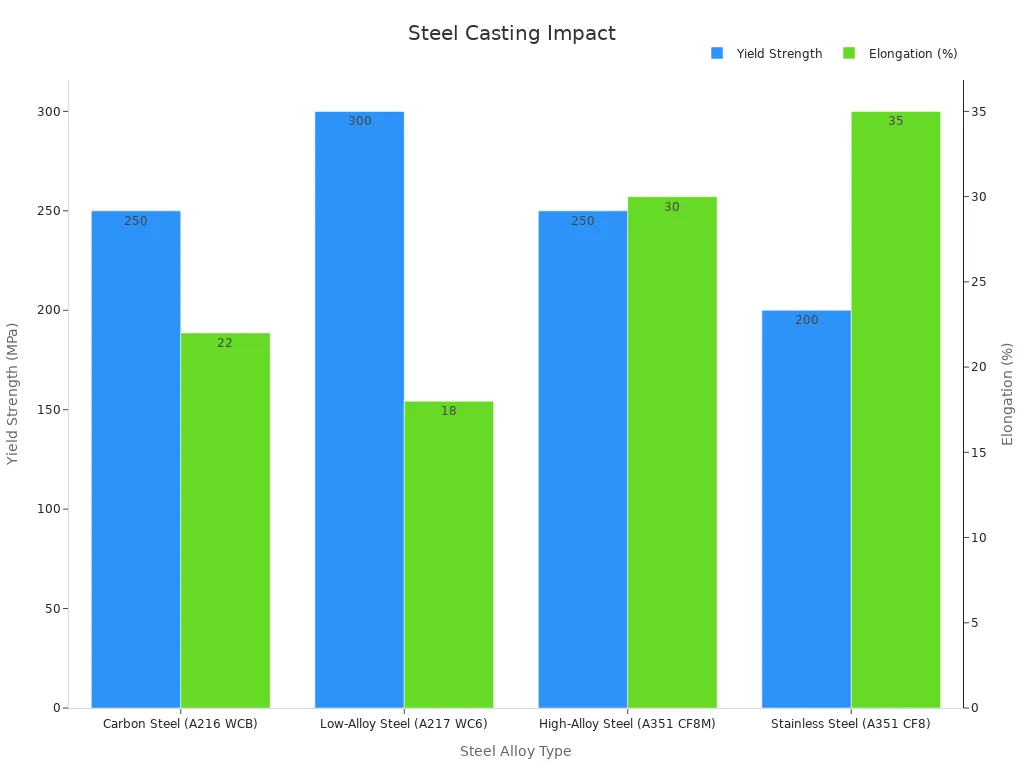

Steel Casting Material

Simbi yekukanda zvinhu inounza musanganiswa wesimba, ductility, uye kuoma. Vanhu vanosarudza simbi yemagiya, zvitubu, uye zvikamu zvemotokari nekuti inokwanisa kubata zvese kunetsa uye kumanikidzana. Izvo zvinhu zvesimbi zvinoshanduka nearoyi akasiyana uye marapirwo.

| Steel Alloy Type | Goho Simba (MPa) | Tensile Simba (MPa) | Elongation (%) | Corrosion Resistance |

|---|---|---|---|---|

| Carbon Steel (A216 WCB) | 250 | 450-650 | 22 | Murombo |

| Yakaderera-Alloy Steel (A217 WC6) | 300 | 550-750 | 18 | Fair |

| High-Alloy Steel (A351 CF8M) | 250 | 500-700 | 30 | Excellent |

| Stainless Simbi (A351 CF8) | 200 | 450-650 | 35 | Excellent |

Kuita kwesimbi kunoenderana nekuti inogadzirwa sei. Kukurumidza kutonhora kunogadzira zviyo zvidiki, izvo zvinoita kuti simbi isimbe. Kurapa kwekupisa uye nzira dzekukanda dzakangwarira dzinogona zvakare kugadzirisa kuomarara uye kuderedza kuremara senge pores.

Aluminium Casting Material

Aluminium casting material yakakurumbira nokuda kwekureruka kwayo uye kushanduka. Inowanikwa muzvikamu zvemotokari, mafuremu endege, uye zvemagetsi. Aluminium inomira kunze kune yayo yakanaka simba-ku-huremu reshiyo uye yakanakisa kuramba ngura.

| Property/Aspect | Cast Aluminium | Cast Steel | Grey Iron |

|---|---|---|---|

| Density | 2.7 g/cm³ | 7.7–7.85 g/cm³ | 7.1–7.3 g/cm³ |

| Tensile Simba | 100–400 MPa (kusvika 710 MPa yemamwe alloys) | 340–1800 MPa | 150–400 MPa |

| Melting Point | 570–655°C | 1450–1520°C | 1150–1250°C |

| Thermal Conductivity | 120–180 W/m·K | Pakati nepakati | ~46 W/m·K |

| Electrical Conductivity | Kugona | Murombo | Murombo |

| Machinability | Easy | Pakati nepakati | Zvakanaka asi brittle |

| Corrosion Resistance | Excellent | Pakati nepakati | Murombo |

| Vibration Damping | Pakati nepakati | Kugona | Excellent |

| Mutengo | Yakaderera pakugadzirwa kwehuwandu | High | Pakati nepakati |

- Benefits:

- Inogadzira zvimiro zvakaoma nehupamhi hwepamusoro.

- Inochengetedza simba nekuda kwenzvimbo yakaderera yekunyungudika.

- Inoramba corrosion, saka inogara kwenguva refu kunze.

- Zvakanaka pakugadzirwa kwepamusoro-soro.

- Kuganhurirwa:

- Haina kusimba sesimbi.

- Inogona kuva brittle mune mamwe alloys.

- Inoda kudzora nekungwarira kudzivirira kukanganisa senge porosity.

Statistical ongororo inoratidza kuti kunaka kwealuminium kunyunguduka uye kuvapo kwehurema kune kukanganisa kukuru pakusimba uye kuoma. Mainjiniya anoshandisa bvunzo dzakakosha uye software kutarisa nekuvandudza kunaka kwekukanda.

Copper Casting Material

Copper casting material inozivikanwa zvikuru nokuda kwemagetsi uye kupisa kwayo. Vanhu vanoshandisa copper castings muzvikamu zvemagetsi, pombi dzemvura, uye zvinhu zvekushongedza. Mhangura alloys, senge bhuronzi nendarira, inopa simba rakawedzerwa uye zvirinani kusakara.

| Alloy Muenzaniso | Electrical Conductivity (% IACS) | Microhardness (Vickers) | Goho Simba (MPa) |

|---|---|---|---|

| EML-200 | 80% | Kuenzaniswa neEMI-10 | 614 ± 35 |

| EMI-10 | 60% | Inofananidzwa neEML-200 | 625 ± 17 |

Mishonga senge yakadzika undercooling inogona kuwedzera conductivity pasina kurasikirwa nesimba. Kuwedzera zvinhu zvakaita se zinc kana tini zvinogona zvakare kuvandudza kupfeka kuramba uye kusimba. Copper castings inoshanda zvakanaka munzvimbo dzakaoma nekuti inodzivisa ngura, kunyanya kana yakasanganiswa nedzimwe simbi.

Magnesium Casting Material

Magnesium casting material ndiyo yakareruka pane ese masimbi ezvimiro. Yakanakira zvikamu zvinoda kusimba asi zvisingareme, senge mumotokari, ndege, uye zvemagetsi. Magnesium alloys ane yakakwira simba-ku-huremu reshiyo uye ari nyore kuita muchina.

- Zvinokosha:

- Yakareruka kwazvo, iyo inobatsira kuchengetedza mafuta mumotokari.

- Kuoma kwakanaka uye castability.

- Yakakwirira simba rakananga, kunyanya mumakaseti alloys.

Miedzo yekuyedza inoratidza kuti kuwedzera maburi kana maumbirwo akakosha anogona kuita kuti magnesium iwedzere kureruka pasina kurasikirwa nesimba rakawanda. Nekudaro, magnesium inogona kukanganisa zviri nyore, saka machira kana alloying zvinhu zvinowanzo shandiswa kuidzivirira.

Zinc Casting Material

Zinc yekukanda zvinhu inowanzoshandiswa kune zvidiki, zvakatsanangurwa zvikamu. Zviri nyore kukanda uye kuzadza mold zvakanaka, zvichiita kuti zvive zvakanaka kune magiya, matoyi, uye hardware. Zinc alloys inopa simba rakanaka uye kuoma kwehuremu hwavo.

- Zvakanakira:

- Yakanakisa kugadzira maumbirwo akaomarara.

- Good corrosion resistance.

- Low melting point inochengetedza simba panguva yekukanda.

- Zvinetso:

- Haina kusimba sesimbi kana aluminium.

- Inogona kuita brittle nekufamba kwenguva, kunyanya mumamiriro ekutonhora.

Zinc castings yakajairika mumaindasitiri emotokari nemagetsi nekuti anosanganisa kurongeka nemutengo-kushanda.

Plastic Casting Material

Plastic casting material inovhura sarudzo dzakawanda dzekugadzira. Hairemi, inopikisa ngura, uye inogona kutora chero chimiro. Vanhu vanoshandisa mapurasitiki akakandwa mumidziyo yekurapa, zvinhu zvevatengi, uye zvikamu zvemotokari.

- Mechanical Properties:

- Kusimba, kuoma, uye kuomarara zvinoenderana nerudzi rwepurasitiki uye kuti inogadzirwa sei.

- Kuwedzera mafiibha senge kabhoni kana girazi kunogona kuita kuti mapurasitiki awedzere kusimba.

| Property / Material | Woodcast® | Synthetic Casting Materials | Plaster yeParis (PoP) |

|---|---|---|---|

| Kusimbisa Simba | High | Lower | Brittle |

| Tensile Simba | Lower | Higher | Brittle |

| Flexural Strength (MPa) | 14.24 | 12.93–18.96 | N/A |

| Kuramba Mvura | Kugona | Inosiyana | Murombo |

Plastic castings inogona kubata mvura uye kupisa zvakanaka, zvichienderana nezvinhu. Mimwe haina chepfu uye yakachengeteka kuti ishandiswe pakurapa. Mamwe anogona kunge aine makemikari anoda kunyatsobatwa.

Ceramic Casting Material

Ceramic casting material inomira kunze kwekugona kwayo kubata kupisa kwakanyanya. Ceramics yakaoma, isingapfeki, uye haina ngura. Vanhu vanoashandisa mumagetsi, muchadenga, uye kunyange zvishongo.

- Thermal Properties:

- Inogona kumira tembiricha inosvika 1300°C.

- Yakanakisa yekudzivirira uye kupisa nhovo.

- Resilience:

- Flexible Ceramic fibers inogona kushandiswa mukushandiswazve insulation ye spacecraft.

- Advanced Ceramics inosanganisa simba rakawanda neiyo yakaderera thermal conductivity.

Vatsvagiri vakagadzira zvinhu zvitsva zveceramic izvo zvese zvakasimba uye zvinochinjika, zvichiita kuti ive yakanakira nzvimbo dzakanyanyisa senge nzvimbo kana kugadzirwa kwepamusoro-soro.

Ceramic casting materials inochengetedza chimiro chavo uye simba kunyange pasi pekupisa kwakanyanya, izvo zvinoita kuti zvive zvakakosha kune zvakawanda zvemazuva ano zvinoshandiswa.

Kusarudza iyo chaiyo yekukanda zvinhu inoumba mhando yechigadzirwa, mutengo, uye kuita. Mainjiniya anofananidza nzira dzekukanda uye zvivakwa vachishandisa matafura uye chaiyo-yepasirese nyaya zvidzidzo kuenzanisa chinhu chimwe nechimwe nekushandisa kwayo kwakanyanya. Kuziva izvi kunobatsira zvikwata kugadzira zvikamu zviri nani, kuchengetedza mari, uye kudzivirira kukanganisa kunodhura.

FAQ

Ndeupi musiyano mukuru pakati peferrous uye isiri-ferrous casting materials?

Ferrous zvinhu zvine iron. Zvisiri-ferrous zvinhu hazviiti. Mhando dzeferrous dzinowanzorema uye dzinoita ngura nekukurumidza. Mhando dzisina-ferrous dzinodzivisa ngura uye dzinonzwa dzakareruka.

Sei mainjiniya achisarudza aluminium yekukandira?

Aluminium inorema zvishoma pane simbi. Inodzivisa ngura uye inoumba nyore nyore. Mainjiniya anozvifarira zvezvikamu zvemotokari, mafuremu endege, uye zvemagetsi.

Mapurasitiki nemakeramic anogona kubata kupisa kwakanyanya?

Ceramics inobata kupisa kwakanyanya. Purasitiki inowanzonyunguduka pakudziya kwakaderera. Mainjiniya anotora ceramics emahovhoni kana injini, nepo mapurasitiki achienderana nemabasa anotonhorera.

Nguva yekutumira: Jun-17-2025